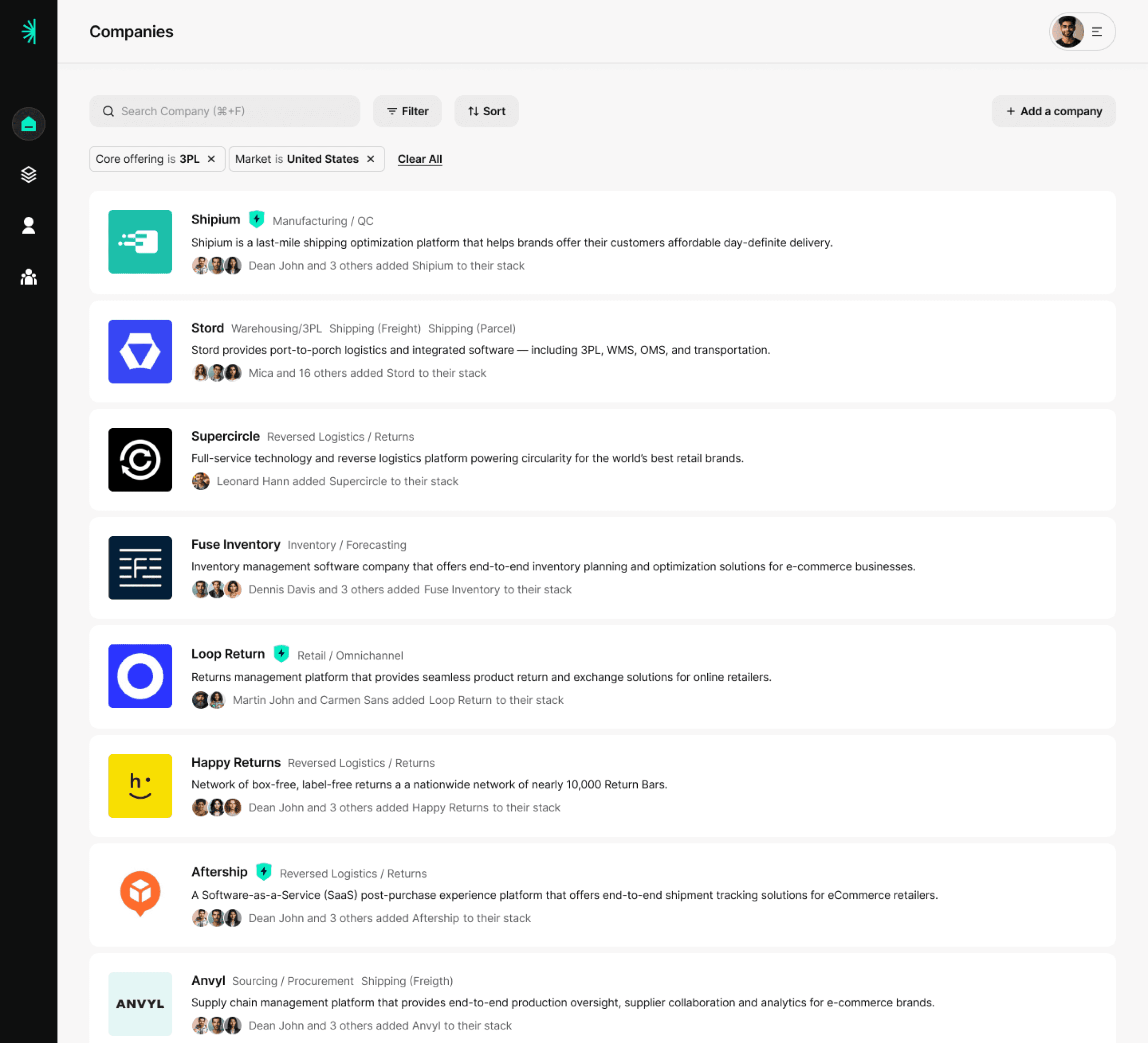

Even if you don’t need suppliers today, it’s never too early to start getting familiar with who is in the field.

Emily Sewell

TLDR:

Supplier sourcing starts well before you need the supplier. Get leads through your network, learn the players, and visit facilities before you think you need to — so when it does become urgent, you can move quickly.

The setup

Emily Sewell was the VP of Operations at Hubble, a D2C supplier of contact lenses.

As the company grew, they wanted to add to their portfolio of lens types, including some technology that wasn’t supported at their current contract manufacturers.

It fell upon Emily to discover, vet, and close partnerships with new manufacturers who could serve their needs.

What happened

The first step of the process was to build a list of prospective vendors to diligence. Having been at Hubble for 4.5 years, Emily came in with a head start, having met many of the players already (and even having visited some of their facilities in Asia).

After throwing a wide net, the next step was to knock out candidates who failed some basic checks. Specifically, Emily looked to eliminate suppliers who:

Didn’t actually have the technology they needed

Couldn’t scale capacity in a way that would comport with Hubble’s sales forecasts

Didn’t have the necessary FDA approval to manufacture product for the US

For the remaining few candidates, Emily dived into deeper diligence:

Manufacturing constraints like capacity ramp times, obligations to other customers, etc.

Contractual and financial terms like MOQs, exclusivity constraints, volume-based pricing breaks, and invoice terms.

Throughout this process, Emily got to know the teams at each company and was also able to develop a gut feel for who was the right fit.

The results

👉 Hubble was able to expand its product line with the right supplier partners.

Key lessons

✅ Start sourcing suppliers well before you need them

Even if you don’t need suppliers today, it’s never too early to start getting familiar with who is in the field. Having name-recognition of your potential partners means you can ask about them if they come up in conversation, swing by their site if you happen to be doing a local factory tour, recognize their rep if you meet them at an event — all things that will later help build your gut feeling about the supplier.

✅ Your network is the best source of leads

While supplier databases do exist, they lack the critical social context of your trusted network. Before diving into any kind of top-down research, spend a few moments reaching out to people you know who may have a view on the best suppliers.

✅ There’s no substitute for a site visit

Meeting a supplier in-person is worth 1,000 phone calls. Better yet is seeing how they run their operations. Travel is expensive and tiring (especially if you’re flying to far-away places) but worth every penny for larger commercial relationships.